Furniture Casters Manufacturer

Techin is a premier manufacturer of furniture casters, offering a wide range of products including Nylon casters, PP casters, Office chair casters, twin wheel casters, and stem ball casters. Our caster factory in China adheres to ISO, Reach, PAHs, RoHS and other EN standards, ensuring high-quality products that meet customer-specific requirements. Our products have been sold worldwide for a variety of applications in furniture, office equipment, medical devices, and retail displays.

Nylon Swivel Plate Casters

Non-Swivel PP Plastic Casters

Floor Protector Rubber Casters

Twin Wheel Office Chair Caster

Office Chair Casters

Modern Minimalist Casters

Side Mount TPR Caster

Swivel Stem Ball Caster

Let's Talk About Your Caster Needs

The Ultimate Guide Of Furniture Casters

Everything you need to know about furniture casters, from selection to installation and maintenance.

What Are Furniture Casters

Basic introduction and overview

Types and Functions

Different types and their uses

Parts and Components

Understanding caster anatomy

Common Materials

Material properties and selection

Caster EU Standards

Quality and safety standards

Caster Lifecycle

Durability and maintenance

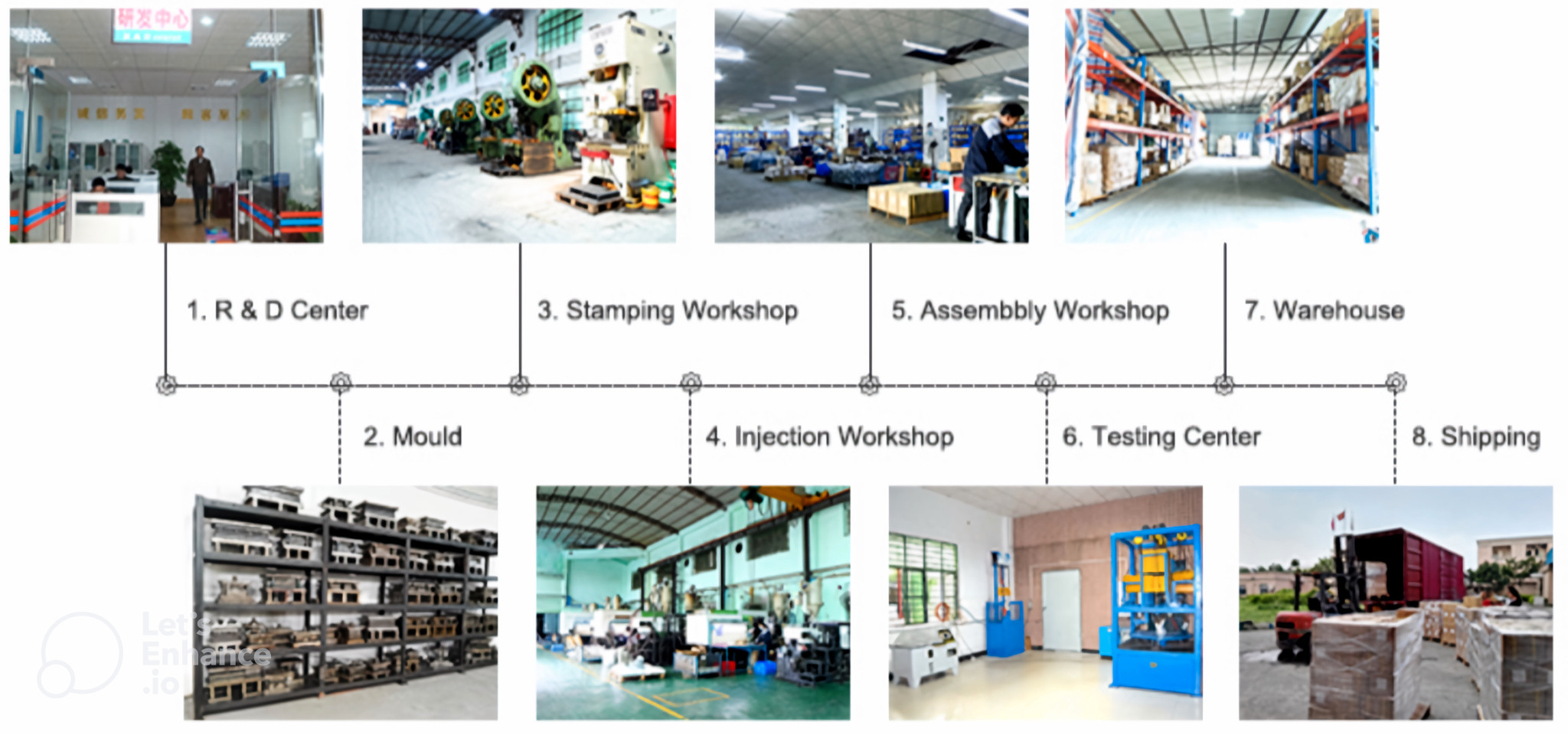

Production Process

Manufacturing workflow

Caster Selecting Guides

How to choose the right caster

Common Pitfalls

Mistakes to avoid

FAQ

Frequently asked questions

What Is It?

Furniture casters are essential components that allow furniture to move effortlessly across various surfaces. They reduce the effort required to relocate furniture and help prevent damage to flooring. Casters are available in different materials, sizes, and load capacities to suit diverse applications.

The right caster can enhance the functionality and lifespan of furniture, making it more versatile and user-friendly. The following section discusses everything you need to know about furniture casters, including the different caster functions and general caster parts commonly used in furniture applications.

Common Types

Furniture casters perform multiple functions within their application environment. Understanding the unique functions of different casters can help in selecting the right one for your needs.

Mobility

Allowing furniture to be easily moved from one location to another.

Stability

Providing a stable and secure foundation to prevent tipping or accidental movement.

Flexibility

Enabling furniture to pivot and turn smoothly.

Support

Bearing the weight of the furniture and any additional load.

Fixed Casters

Fixed casters provide stability and controlled movement, making them perfect for furniture that requires straight-line movement. They are often used in conjunction with swivel casters to provide a combination of mobility and stability. Common applications include storage racks and heavy machinery.

Swivel Casters

Swivel casters provide excellent mobility and flexibility, making them ideal for furniture that needs to move frequently and navigate tight spaces. They are commonly used in office chairs, rolling tables, and portable equipment.

Brake Casters

Brake casters ensure safety and stability by preventing the wheels from rolling or swiveling. They are essential for furniture that needs to stay securely in place when not in use. Brake casters are commonly used in medical equipment, retail displays, and workstations.

Caster Components

Furniture casters consist of several smaller parts. While specific caster types contain certain components definitive to that design, all furniture casters share major components. Understanding each component helps in choosing the right caster for specific applications.

Wheel

The main component that comes into contact with the floor. Made from materials such as rubber, plastic, or metal, depending on the application.

Axle

Connects the wheel to the caster frame and allows for smooth rotation.

Bearing

Ensures the wheel rolls smoothly and reduces friction.

Frame (Yoke)

The structure that holds the wheel and attaches to the furniture.

Mounting Plate

Connects the caster to the furniture, available in various styles such as top plates, stems, or threaded rods.

Caster Materials

Furniture casters are made from various materials, each offering different benefits and suited for specific applications. Choosing the right material ensures optimal performance, durability, and protection for flooring.

Common Furniture Castor Materials - Comparison Table

| Material | Hardness | Load Capacity | Noise Level | Floor Compatibility | Wear Resistance | Typical Applications | Key Advantages | Considerations |

|---|---|---|---|---|---|---|---|---|

| Rubber | Soft | Medium | Very Low | Excellent | Medium | Home furniture, hotel furniture, premium interiors | Quiet operation, shock absorption, non-marking | Moderate wear life compared to PU |

| PA (Nylon) | Very Hard | Very High | High | Best suited for carpeted or protected floors | Excellent | Industrial furniture, storage cabinets, carpeted floors | High load capacity, outstanding durability, low rolling resistance | Better suited for non-delicate floor surfaces |

| PP (Polypropylene) | Hard | Light Duty | High | Suitable for non-sensitive floors | Basic | Light-duty furniture, cost-focused products | Lightweight, economical, easy to manufacture | Designed for light-load applications |

| PVC | Medium | Light to Medium | Medium | Suitable for general indoor floors | Moderate | Light furniture, decorative use | Cost-effective, flexible, basic noise reduction | Recommended for moderate load requirements |

| TPR (Thermoplastic Rubber) | Soft | Medium | Low | Excellent | Medium | Home furniture, office furniture, wooden floors | Quiet, floor-friendly, good grip | Optimized for medium-load furniture |

| PU (Polyurethane) | Medium-Hard | High | Low | Very Good | Excellent | Office chairs, cabinets, premium furniture | Durable, high load capacity, balanced performance | Higher material cost compared to basic plastics |

Caster Standards

In the caster industry, several European standards serve as guidelines to ensure the quality, safety, and environmental compatibility of products. Here, we provide an overview of some pivotal standards that are commonly adhered to:

These standards are integral in guiding manufacturers to produce products that are not only of high quality but also safe and environmentally responsible. Adherence to these standards is often seen as a mark of reliability and trustworthiness in the industry.

Caster Lifecycle

In the realm of caster usage, understanding the lifecycle of casters is pivotal in planning proactive maintenance or replacements, thereby mitigating potential risks associated with caster failures. Here, we delve into the various factors that influence the durability and lifespan of casters:

Material Considerations

The materials used in the construction of casters significantly influence their lifespan. For instance, casters that frequently come into contact with water, corrosive liquids, or air tend to have a shorter lifespan. Utilizing stainless steel rigs can offer more years of service and maintain better presentation, preventing rust and corrosion.

Maintenance Practices

Proper maintenance practices can extend the lifecycle of casters. Regular check-ups and timely replacements can prevent issues such as inventory damage, product flow interruptions, and potential workplace injuries. It is recommended to change casters at certain intervals to avoid downtime.

Appropriate Caster Selection

Choosing the right caster for the specific job at hand is crucial. Different applications demand different types of casters, and selecting the appropriate one can prevent premature wear and tear, thereby extending the caster's lifespan.

Environmental Factors

The environment in which the caster operates can also affect its durability. Factors such as exposure to water and corrosive liquids can shorten the caster's lifespan. Understanding the specific environmental conditions and selecting casters accordingly can be beneficial in prolonging their service life.

Production Process

Caster and wheel, often overlooked, are integral to various aspects of daily life. From shopping carts to industrial equipment, these simple yet efficient components serve as the unsung heroes of mobility. The production process behind caster wheels is a blend of cutting-edge technology and expert craftsmanship.

Research and Development

Engineers and designers continuously explore new materials and methods to enhance caster wheel performance.

Mold Creation

Skilled artisans employ advanced technology to craft molds that define the dimensions of caster wheels.

Stamping and Injection Workshops

High-tech machines transform raw materials into caster components. Stamping creates durable metal pieces, while injection molding produces resilient plastic parts.

Assembly Workshop

Skilled workers meticulously assemble the caster wheels, ensuring they roll smoothly and securely.

Testing Center

Each caster wheel undergoes rigorous testing to meet and exceed industry standards, evaluating performance, durability, and safety.

Warehouse & Shipping

Approved caster wheels are stored in organized warehouses and shipped worldwide, providing effortless mobility for various applications.

Selecting Casters

Selecting the right caster and installing it correctly is a vital aspect in ensuring the longevity and functionality of your equipment. We outline a systematic approach to guide you through the process:

1. Determine Your Product and Mounting Type

The first step involves identifying the type of product you are working with and the appropriate mounting method. Different products may require varied mounting techniques, and understanding this is crucial in selecting the right caster.

2. Understanding Load Capacity

Before selecting a caster, it is essential to determine the load capacity it needs to handle. The load capacity is calculated using a specific formula that considers various factors including the deadweight of the transport unit, the maximum additional load, and the number of wheels or casters used.

3. Select Your Tread Material

The tread material significantly influences the operational comfort, smooth-rolling performance, and resistance characteristics of the wheels or casters. It is vital to choose a tread material that is softer than the floor to prevent damage.

4. Determine Maneuverability

Understanding the maneuverability factors such as starting, rolling, and swivel resistance is crucial in selecting the right caster. These factors are influenced by various elements including wheel diameter, load, floor condition, and bearing type.

5. Select the Bearing Type

The bearing type is a critical aspect that affects the rolling characteristics of a wheel. Different bearing types, such as plain bore bearing, roller bearing, and central ball bearing, offer varied performance characteristics and are suitable for different applications.

6. Consider Environmental Influence

The environmental conditions where the caster will be used should be considered, especially in cases where the components may come into contact with aggressive substances. Factors such as chemical resistance, temperature, and humidity can influence the choice of caster.

7. Additional Options and Requirements

Depending on your specific needs, you might require additional features such as locking systems for rolling and/or swivel motions, or brake systems. Understanding these additional requirements is vital in selecting the right caster.

Common Pitfalls

Ordering casters and wheels for your business might seem straightforward, but there are several common pitfalls that can complicate the process, especially for hardware supermarket buyers and caster distributors in Europe. Being aware of these issues can save you time, money, and resources while ensuring that you receive products that meet your specific needs.

Ignoring Quality Standards

Not ensuring products meet European standards and certifications

Narrow Product Selection

Limited range of products and customization options

Lack of Custom Options

Inability to provide customized solutions for specific needs

Poor Communication

Language barriers and slow response times

Unclear Payment Structure

Complex payment terms and hidden costs

Why Choose Techin?

Getting the right casters and wheels for your business is more than just clicking 'Get A Quote'. It's about making smart choices, and that's where Techin comes into play. We offer you a wide range of top-notch products, flexible custom options, and straightforward payment plans, all while keeping the lines of communication open.

By choosing Techin, you're opting for a supplier that gets the ins and outs of the B2B world. We're here to make your buying process hassle-free and help you steer clear of common mistakes, setting you up for success in your business.

Frequently Asked Questions

To continue to provide valuable information for our B2B clients, here are answers to common questions about our furniture casters.

Do you offer free samples?

Yes, we offer product samples to give you a firsthand experience of the quality and variety we bring to the table.

Do you have any certifications?

Certainly, our products proudly bear recognizable certifications like EN840, REACH, RoHS, PAHs, EN12530 etc. These symbols of excellence guarantee that you receive products that meet international standards.

Is there a warranty period for your products?

All of our products come with a standard warranty period, reinforcing our commitment to quality and customer satisfaction.

How do you ensure timely delivery of orders?

We have a streamlined production schedule and robust logistics partnerships to ensure that your orders are delivered on time, every time.

Is it OK to print my logo on casters?

Sure. We could build the molds and fixtures upon your sample or technical drawings, add your logo on fork or wheel, and pack the casters in your branded carton.

Any Questions? Contact Us!

Get in touch with our team for personalized assistance with your furniture caster needs.